Australia is the world’s hottest, driest continent. Ambient dry bulb temperatures exceeding 40 Degrees C are common for several months of the year in inland areas and, in the hot, humid, tropical regions, workplace temperatures exceeding 28 Degrees C WB and heat stress related incidents are also frequent.

Hot working conditions in mines are common. The reasons include the hot surface climate, “auto compression” of air as it enters deep mines, the very intense use of high-powered diesel equipment in confined spaces and the high moisture pick-up in the ventilating air, which increases the humidity and wet bulb temperature and consequently the heat stress on workers.

At risk workers are not only in the mining industry they include farmers, construction workers, fire-fighters, miners, soldiers, and manufacturing workers working around process-generated heat. The potential impacts of workplace heat exposure are to some extent underestimated due to the underreporting of heat illnesses.

Heat related issues are the greatest problem facing OH&S in industry today, and with the forecast of longer, hotter summers the problem will only become more relevant. This problem is very costly to industry, not only through workers away from the workplace recovering from heat related illness, but also form lost productivity through longer, more regular breaks and fatigue.

Much progress has been made with the awareness and control in heat stress situations. However, even the most efficient measures now in place are very restricted in their effectiveness.

Regular fluid replacement is the most common practice in dealing with heat stress today. While it is most important to maintain a regular, controlled fluid replacement regime, there is only so much fluid that can be replaced. In an attempt to control its temperature the body will increase sweat rate, more fluid will come out than can be replaced.

Other methods include more regular breaks during activity, fabric choice in protective clothing and attempts to make the work space cooler through mechanical means. These methods, while of some assistance, are short lived and costly in lost productivity.

There is a more practical answer to controlling heat stress in the workplace, greatly reducing heat sickness, without sacrificing productivity. An effective method, combined with fluid replacement, of heat stress management without the loss of productivity and sick days.

THE ARCTIC HEAT BODY COOLING VEST

Arctic Heat is the leader in personal cooling wear, especially with the cooling vest. Arctic Heat has spent many years in research and development resulting in a revolutionary cooling vest that is easy to use and maintain, inexpensive, very comfortable and lightweight to wear while working.

The vest works by mimicking the body’s natural cooling process of keeping the skin dry and cool. It is made from two body cooling fabrics, Poly Interlock and Micromesh, which have a wicking effect. This wicking effect transfers moisture form the skin to the front of the garment keeping the skin almost completely dry. A crystal is built into strategically placed pockets in the vest which activates into a gel when soaked in water; this gel holds the temperature it is introduced to for long periods, cooling the skin, and controlling core temperature. For example if the activated (gel) vest is placed into a freezer the gel will freeze, if it is placed into ice water it will take on this temperature. The vest weighs approximately 1 kg making it light and non-restrictive to wear. If needed the vest can also be used as a heating vest, no other technology can be used both ways nor is there anything else available as specific as this vest.

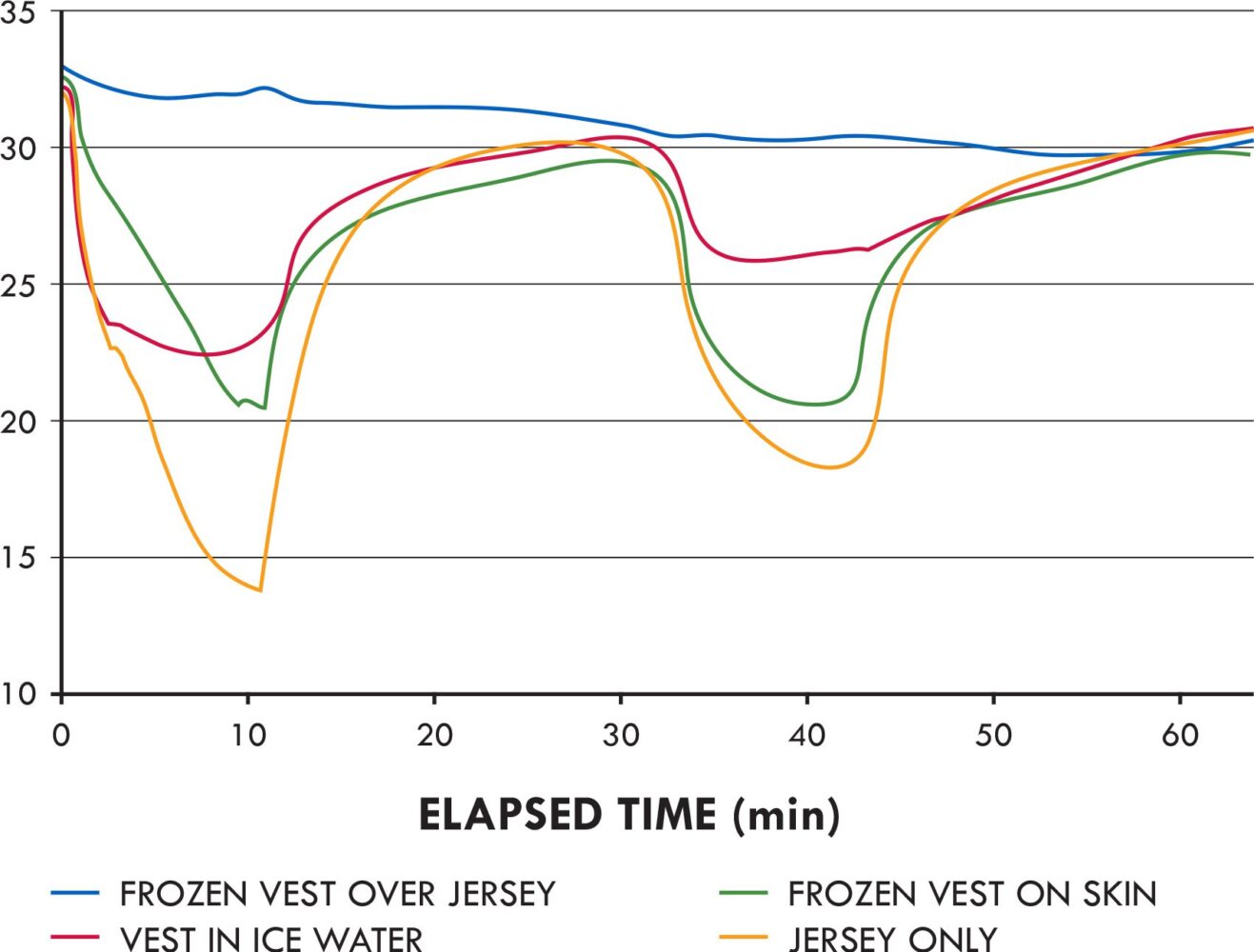

Independent testing carried out on the vest has proven how quick and effective it works. The vest, when placed directly against the skin can drop skin temperature by up to 17 degrees C in about 7 minutes and if placed over a light singlet or shirt by up to 13 degrees C. The vest can be used before, during or after activity which ever suites the wearer best. When the vest is removed, it takes an extended period of time during high activity for the skin to return to ambient temperature. This will give the worker a prolonged cooling effect and increase the cooling time form the heat. This time is longer when the activity is not as heavy or consistent. The generic results show that by using the vest heart rate is 10 beats/minute lower and the amount of sweating is reduced by 13%. The Arctic Heat Body Cooling Vest reduces physiological and subjective strain during activity in heat, and promotes efficient workload by up to 10%. The vest greatly reduces the chances of heat injury occurring in an efficient comfortable manner.

The above graph, part of independent CSIRO testing, shows the effectiveness of the vest in all its applications. For most effective operation, the vest is at its best when frozen, but can be very effective when placed into a thick slurry of ice water (mainly ice). Ultimately if small freezers were available for the vests only, they would be at their maximum capacity all day. The vests are used very successfully in all areas of the mining industry. The vest is so versatile it can be used with or without mechanical cooling devices (freezer), around a camp, or in remote work areas. The Arctic Heat cooling vest is used worldwide in sport, industry, medical and military applications; in fact anywhere that heat is a problem. In summary the Arctic Heat Body Cooling Vest is an effective efficient tool in the prevention of heat injury.

MAJOR BENEFITS IN USING THE ARCTIC HEAT BODY COOLING VEST:

- Lowers skin temperature by up to 17 degrees C

- Conserves fluids

- Stabilizes core temperature

- Lightweight and easy to use

- Increased maximum work output

- Made from specific body cooling materials

- Can be used just as effectively around a camp or in remote areas

For further information go to www.arcticheat.com.au or get in touch via email admin@arcticheat.com.au or phone (07) 5520 0146.

Add Comment