Augmented and virtual reality is set to change the future of mine safety through immersive learning according to industry experts.

The next generation of mining maintenance personnel are beginning to use AR and VR to improve their safety skills and knowledge in complex mining maintenance tasks.

Studies on the millennial generation is showing that they are looking for more experiential learning. This is perhaps not surprising, given that they — and the generations following them — grew up in a digital age.

US-based safety giant, Honeywell, is leading the charge in AR/VR integration with more than three years of in-house experience in the field.

“We work with partners that develop the hardware for us, but most of our AR/VR technologies are developed in-house,” Honeywell regional business director Aonghus Keegan said recently.

“It’s very exciting but also a natural progression in safety. That experience is not available in any other way except for being on the job”

“The scenarios you capture on VR are occurring less often or are an emergency response that you don’t want to be exposed to.”

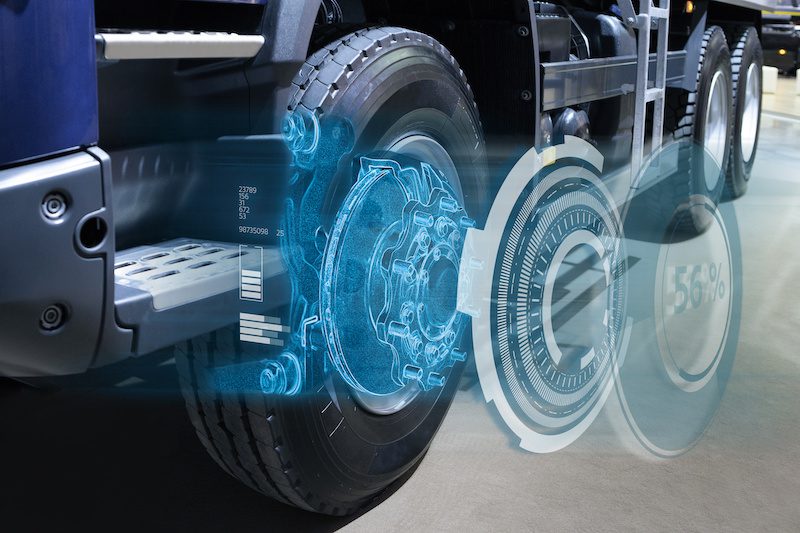

AR/VR technologies already have application

In the mining sector, gaming savvy individuals are set to play an important role across mining operations and already are transferring a range of skills learned through gaming to mining maintenance activities.

The use of AR/VR will allow mining companies to train their staff more effectively and quickly and mitigate potential mine safety issues as they go.

READ RELATED

- Augmented reality to transform mining safety

- How new technology and AI can control rising maintenance costs

- Digital investments, new business models, digital twins and IoT

- Augmented reality to transform work safety

To train new mining maintenance personnel, global safety giant Honeywell has collaborated with Microsoft on a new solution: The Honeywell Connected Plant Skills Insight Immersive Competency.

Here’s a behind-the-headset look on how it works and how it will change mining safety.

The AR/VR gear

Employees wear a Windows Mixed Reality headset that uses Microsoft’s HoloLens, the world’s first and only self-contained holographic computer, to simulate various activities in plant.

How it works to train personel

The software uses a combination of augmented reality and virtual reality, providing a mixed reality experience combined with data analytics.

Simulating on-the-job experience

Workers access activities through virtual environments that are accessed through the cloud offers a natural way to interact and communicate with peers or a trainer. It aims for improving skills retention by 100 per cent and reducing training time by 60 per cent according to Honeywell.

Watch the latest video from Honeywell.

Read more Mining Safety News

Add Comment