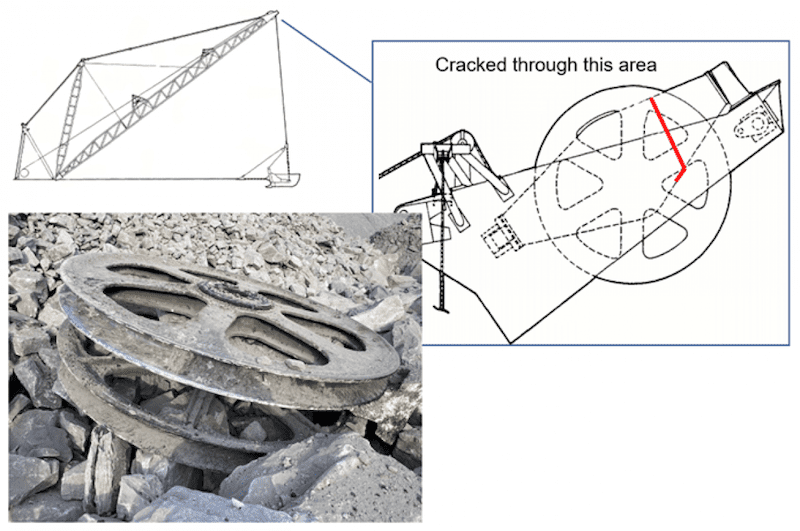

Queensland Coal Inspectorate has issued a safety alert following a major structural failure of the boom point sheaves on a BE1370 dragline, which allowed the sheave assembly to fall from the boom point and land in the pit.

A Coal Mine Worker (CMW) was operating a B1370 Dragline and in the process of slewing with a full bucket (in preparation to dump onto spoil). The CMW heard a loud noise and shortly afterwards the bucket fell to the ground along with a portion of the snapped hoist ropes, followed closely by the boom point sheave assembly.

Worker suffers serious injuries when pinned by continuous miner

Incident | Man basket drops to the ground

The Inspectorate stated that the key issues were a structural defect of the boom point sheave swivel yoke was not identified during routine maintenance. The location of the failure was difficult to visually inspect due to its location and the build-up of grease.

The inspectorate’s recommendations are:

- Regular visual and ultrasonic testing of the boom point sheaves and swivel yoke for cracking, wear and lubrication.

- Regular visual and ultrasonic testing of all upper boom structural connections at the boom point box.

- Attend to all structural cracking immediately as outlined in the OEM Manual.

- Sites must have a structural inspection regime in place that ensures an acceptable level of risk is achieved.

Investigations are ongoing and further information may be published as it becomes available.

Read more Mining Safety News

Add Comment