A government regulator has issued a warning around ensuring equipment used in hazardous areas meets conformity under ANZEx or IECEx Scheme. The warning surrounds the requirement for hazardous area equipment certified outside Australia to be supplied with a conformity assessment document.

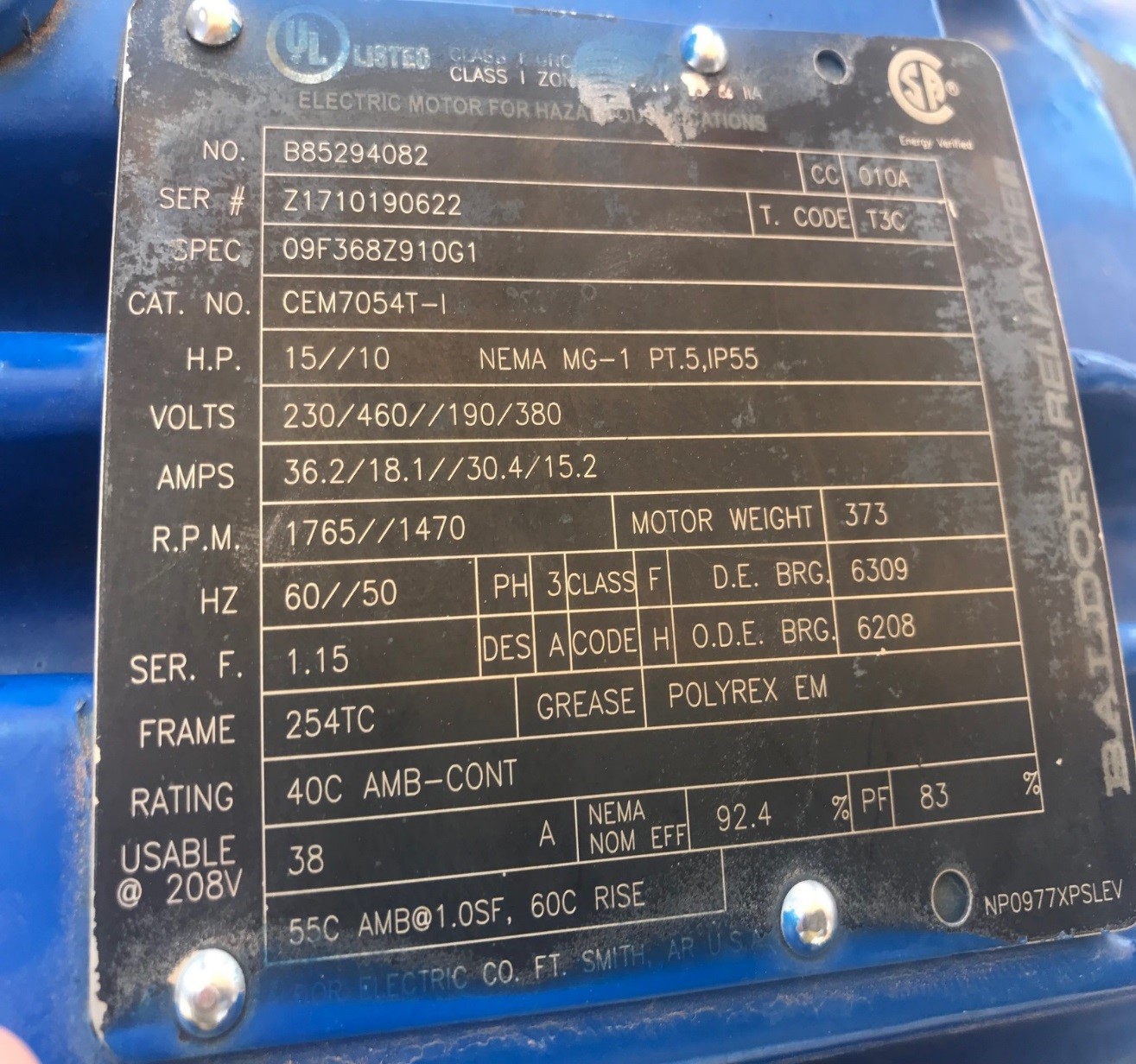

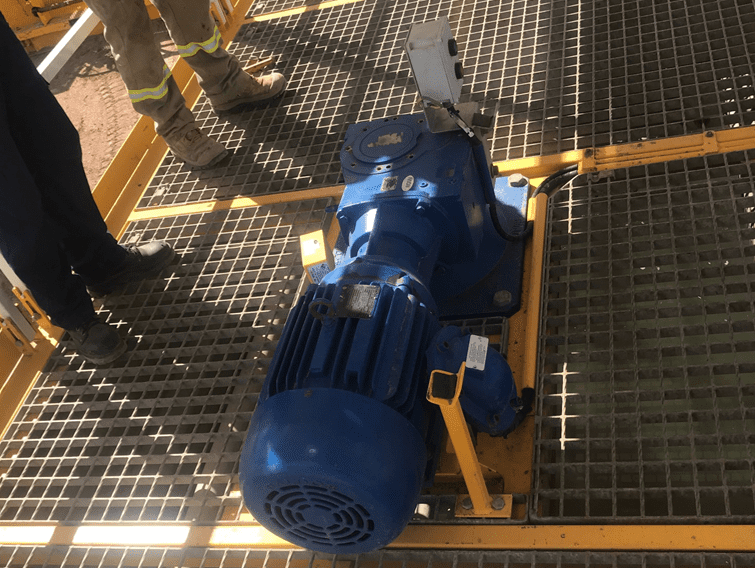

According to the regulator during an inspection of ‘Drill Rig’ Operating Plant, inspectors identified electrical motors installed within a hazardous zone that were not ANZEx or IECEx (International Conformity Assessment Scheme) certified. The motors were marked as UL certified (UL is one of the North American Certification System – See note below).

The regulator says that there was no evidence that a conformity assessment, by a qualified assessor, had been undertaken for the equipment. Under legislative requirements, certifying equipment to meet the requirements for an ANZEx or IECEx certificate is required.

The regulator says that the ‘Operating Plant’ safety management system did include detailed requirements for electrical installations within a hazardous zone to comply with relevant Australian Standards, however, the particular installation did not conform to the requirements of the safety management system implemented for the Operating Plant. The regulator stated that “An acceptable level of risk has not been met.”

Hazards equipment installation in Australia should comply with AS/NZS 60079.14: 2017 Explosive Atmospheres – Design selection, erection and initial inspection.

While there are some similarities between the systems used in North America and Australia, the requirements of Australia’s system make provision for specific equipment used in hazardous areas to have a Conformity Assessment Document.

When selecting equipment for use in hazardous areas Australian mines should seek equipment compliance with Australian Standard AS/NZS 60079. This standard is harmonized with IEC 60079 so that the national certificate of conformity (ANZEx) is accordingly fully harmonized with the international certificate of conformity (IECEx).

The regulator says that “equipment certified to IECEx can, therefore, be used almost without exception in Australia without the need for further testing or hazardous area approvals.”

Further information can be found in AS/NZS 60079.14 or by engaging with an accredited hazardous area auditor.

UL Certification

The Canadian Electrical Code (CEC) and U.S. National Electrical Code (NEC) or NFPA70 specify requirements ‘generally’ aligned with IEC 60079-10.

IEC 60079-10 mandates the standards for hazardous area devices in North America. These standards are slowly changing to fall into line with IEC Ex. Until recently it was impossible to accurately draw parallels between the North American system of Classes and Divisions and those of ATEX and IEC Ex, however, Canada has now fully adopted the 3 Zone system for new equipment and US products can continue to be labelled either way.

Australia does not recognise the system of Classes and Divisions and any usage of equipment certified to North American standards and equipment must have a Conformity Assessment Document completed for each device type and use case.

Images QLD Department of Natural Resources Mines & Energy.

Read more Mining Safety News

Add Comment