Queensland Mines Inspectorate has released a worker who has injured at a coal mine. On 25 August 2020 a Coal Mine Worker (CMW) was deflating an ultra-class rear dump truck tyre using a super large bore IN-80 inflator adaptor tool, also commonly known as a deflator tool (refer to Figure 1). The stem of the inflator adaptor tool has ejected and struck the safety glasses being worn by the CMW. The CMW was startled by the impact and stumbled backwards off a step ladder, falling onto the workshop floor.

Failure to isolate compressed air

Worker seriously injured after falling from roof

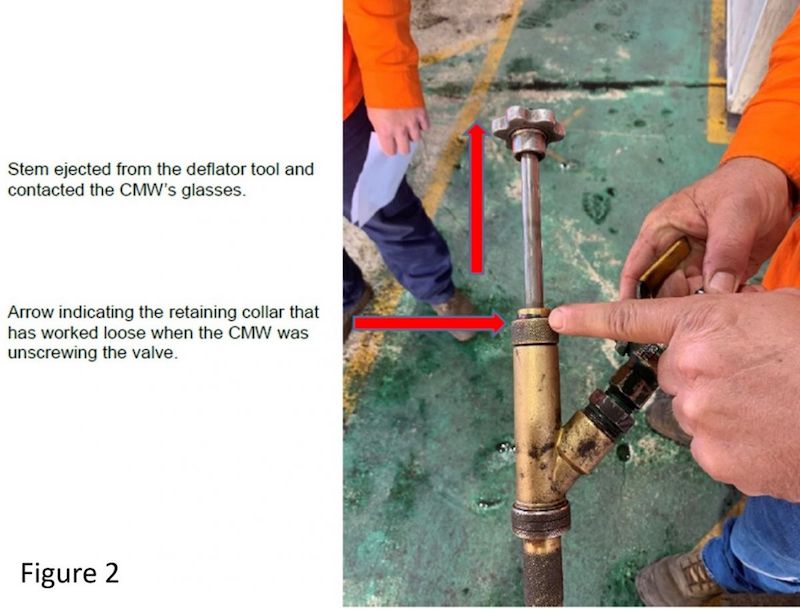

The incident occurred when the worker was turning the handle of the inflator adaptor tool anti-clockwise to remove the valve core, the retaining collar has loosened and separated from the tool body and the stem has been ejected (refer to Figure 2).

The retaining collar of the adaptor tool involved in the incident had a right-hand thread, which when turned clockwise tightened the collar. Turning the adaptor tool handle anti-clockwise caused the collar to also turn anti-clockwise until it disengaged from the adaptor body and the stem ejected under the tyre air pressure.

The inspector stated the key issues are:

- Inadvertent unscrewing of IN-80 inflator adaptor retaining collars was identified by a tyre management company following a similar incident in 2017.

- At the time the tyre management company investigation identified that many experienced tyre fitters had experienced similar events and that the risks appeared to have been normalised and accepted by the workforce.

- The tyre management company worked with the supplier of the inflator adaptor. A safer replacement IN-100 tool for super large bores is available, replacing the IN-80 tool.

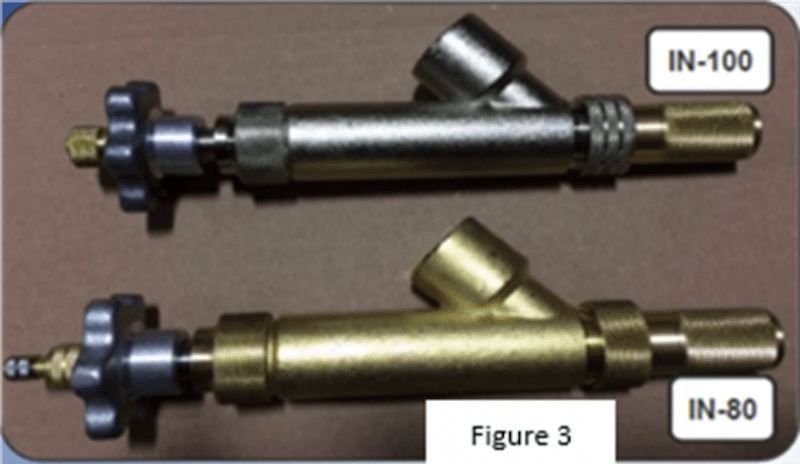

- NOTE: IN-80 and IN-100 inflator adaptor tools look the same (refer to Figure 3).

- Site investigations confirmed that IN-80 tools are still being used by CMWs.

- Instead of ladders, fit for purpose work platforms should be used.

Read more Mining Safety News

Add Comment