A recent lifting incident involving a loader axle assembly has highlighted the requirement for the effective assessment of lifting methods during maintenance operations.

According to the Minex NZ report, two fitters were fitting a 3-tonne front axle assembly onto a loader. A spreader bar was used to allow the correct placement of the two slings on each end of the axle. Each sling was attached to the spreader bar via a 3.2 tonne rated bow shackle.

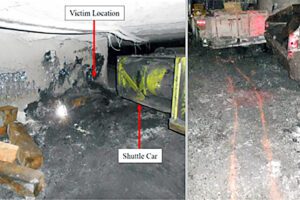

To centre the axle under the bucket lift arms during lifting, the load was picked up and put down multiple times as it was manoeuvred into place. Each time the load was put down the bow shackle on the western end (closest to the camera in the picture) was undone so the sling could be re-run past each of the loader lift arms before being attached to the spreader bar with the bow shackle again.

Once centred, the axle was being lifted off the cribbage when the west side sling dropped, the spreader bar flung around and

landed on top of the loader bucket, and the axle dropped onto the cribbing and then slid off onto the floor.

READ RELATED

- Lifting arm nominated for award

- Lifting safety improved with remote-controlled load orientation

- The situation of gravity | Case study on Perilya Fall Incident

The high potential nature of this lifting incident to result in serious injury to personnel should not be understated. Minex has advised that mine maintenance personnel should ensure:

- Where practical, other devices (e.g. skates etc) for moving axles into place are used that do not require the use of repeated lifts.

- Review lifting processes and where possible replace bow shackles with safety hooks.

- When lifting ensure that no-one is in the fall zone of the item being lifted.

- All workers are trained and regularly assessed as competent in safe lifting procedures.

- You regularly inspect all equipment used for lifting

Source: Minex Safety Alert November 2019

Standards for load rated equipment, lifting and rigging components to minimise lifting incidents

A range of standards should be considered when selecting components for lifting or rigging. AMSJ have provided a basic list below for mines to consider during lifting or rigging activities.

- AS 1353 – Flat Synthetic Webbing Slings

- AS 1380 – Fibre Rope Slings

- AS 1418.2 – Cranes – Serial Hoists and Winches

- AS 2317 – Collared Eyebolts

- AS 1666 – Wire Rope Slings – Product Specification, Care and Use

- AS 2550 – Cranes – Safe Use AS 2741 – Shackles

- AS 2759 – Steel Wire Rope – Use, Operation and Maintenance

- AS 3775 – Chain Slings – Grade T

- AS 3777 – Shank Hooks and Large Eye Hooks – Maximum 60 tonnes

- AS 4344 – Motor vehicles – Cargo restraint systems – Transport chain and components

- AS 4380 – Motor vehicles – Cargo restraint systems – Transport webbing and components

- AS 4497 – Roundslings – Synthetic Fibre – Product Specification, Care and Use

Read more Mining Safety News

Add Comment