Western Australia’s Department of mines industry regulation and safety (DMIRS) has released a report regarding to manned loader falling into an open stope.

In July 2020, an operator was driving a load haul dump (LHD, also known as an underground loader or bogger) in an underground mine

when it fell over the edge of an open stope. The LHD fell approximately 25 metres and the operator sustained fatal injuries.

Floor slump on stope | Incident report

BHP forms heritage body with Banjima native title holders

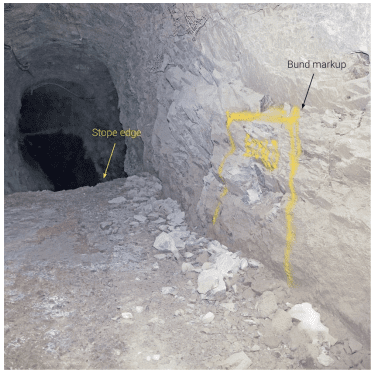

It is understood the operator was preparing to build a safety bund about six metres from the stope edge.

Potential causal factors

There was no physical barrier to prevent the LHD entering the stope.

When operating an LHD, the operator’s forward visibility is limited by the configuration of the machine. This can have implications on an operator’s capacity to see the edge of the open stope as they approach.

There were no effective visual wall markings or delineators to aid the driver in judging the distance to the open stope edge.

Actions required

Mine operators, managers and front line supervisors are reminded of the importance of developing safe systems of work and implementing appropriate controls for all work near open stopes and voids underground. The following actions are recommended:

- use a physical barrier such as a rock bund, engineered steel or concrete barrier, or steel bollards to prevent LHDs and other manned machines entering open stope voids

- a physical barrier must be erected before the open stope is created or changed by firing, and maintained thereafter to prevent access

- develop a safe system of work to place one or more barriers as the stope is mined

- position the physical barrier at an appropriate distance from the stope such that the operator is not exposed to the hazard of going over the edge

- place visual markings and/or delineators on the walls or backs to identify the distance to the stope edge

- use remote LHDs or other types of loaders with better forward visibility, instead of manned LHDs.

Read more Mining Safety News

Add Comment