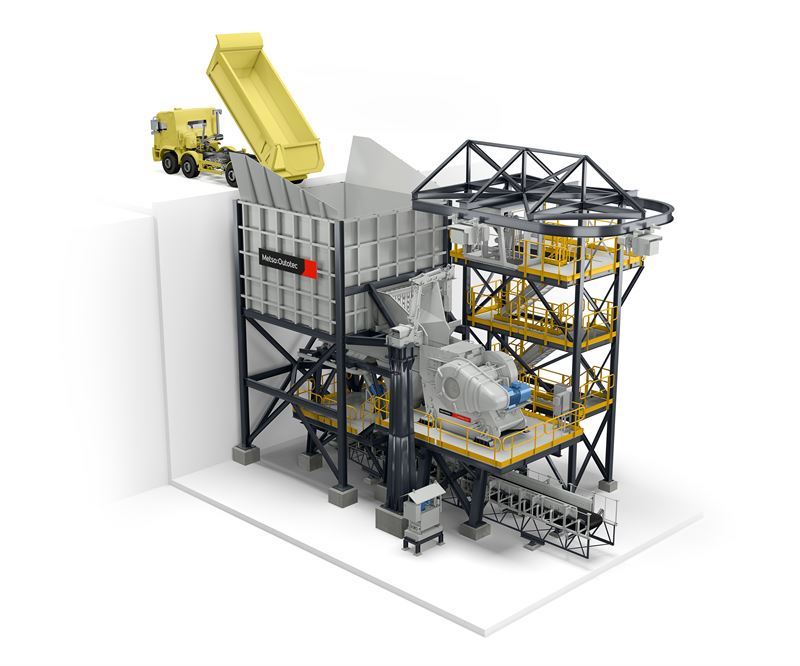

Amarillo Gold Corporation has selected Metso Outotec’s modular FIT™ Station for its Posse Gold greenfield mining project in the state of Goiás in central Brazil. The new game-changing crushing and screening solution was introduced to the markets in 2020, and Amarillo Gold will be the first site where it will be installed. The cost-efficient FIT™ Station has been designed to bring significant savings of resources and time to mining operations.

Metso Outotec’s new model equipped with Komatsu’s sizer technology

Metso Outotec improves process audits and production transparency

“Amarillo Gold has a strong social license to operate in the Mara Rosa property where the Posse Gold project is located. Our aim is to build a modern, sustainable mining operation, and Metso Outotec’s FIT Station fulfils our ambitious targets for the process,” says Arão Portugal, Country Manager at Amarillo Gold.

The FIT™ Station to be delivered to the Posse Gold project has a design capacity of 540t/h of ROM with an average production of 102.000Oz of gold/year (years 1 to 4). The station consists of crushers, vibrating feeders and screens, as well as conveyors and related structures and other equipment.

Amarillo Gold Corporation is advancing two gold projects in Brazil. The Posse Gold project, which has gold resources of approximately 1.2 million contained ounces, is in the company’s Mara Rosa Property in Goiás state. The project will operate an open pit mine and carbon-in-leach operation with dry stack tailings.

“We are very proud to have the honor to work with Amarillo Gold. They are a frontrunner aiming to select the best technology for their project. Metso Outotec’s sustainable FIT™ crushing stations are a good fit with this objective, as they are designed for CAPEX reduction and shorter lead times, with ease of installation and maintenance,” says Guillaume Lambert, Vice President, Crushing at Metso Outotec.

Learn more about mining crushing stations on our webpage.

Add Comment