HIMA has developed a solution based on the tried-and-tested HART communication protocol, enhancing it with security measures compliant with SIL 3. It is the foundation of what experts call ‘safety data intelligence’. By converting sensor data into real-time diagnostic information, you can simplify compliance, identify security vulnerabilities, and even enhance product quality. In this way, you turn safety into value.

Here are three examples of how this concept works:

1. Streamline Field Device Health Analysis

In many instances, it is possible for an error to occur because important information that could have prevented the issue has been overlooked. It could be that your maintenance procedures are ineffective, resulting in a premature failure, or that devices have been allowed to stray outside of predefined parameters. Detailed error diagnostics play a key role in ensuring you avoid any dangerous conditions in your field devices. The new solution enables you to securely use your data to better understand your field devices and implement predictive maintenance, for example.

So, how does this work? While the information isn’t safety-related, it can be used inside the safety instrumented function (SIF) logic as an independent, additional protective measure. An example of this in practice would be maintenance staff receiving a notification via HART that gas sensors are about to fail. Employees can take action in advance to avoid a potentially damaging failure. In this way, you can plan for the future and benefit from predictive maintenance.

With safety data intelligence, your safety system can automatically filter warnings so that your team only receive information that is important for the safety of your plant. As a result, you require fewer internal resources for analysis. This approach also makes it possible to recognise many parameters that would normally require additional software.

An example of this type of factor is the heartbeat sensor integrity (HBSI) value (provided by E+H devices) that can notify staff when maintenance is necessary. In reality, many companies do not expand their systems to cover such parameters. The tools that identify these factors are often not designed with safety in mind and must be backed up again, meaning for many operators, the drawbacks outweigh the benefits. For this reason, only a solution with integrated large-scale parameter monitoring delivers precise diagnoses.

2. Protect Your Field Devices Against Unauthorised Changes

Field devices are normally configured using handheld hardware. In a conventional setup, the devices would not be connected to a safety instrumented system (SIS), but only to the asset management system (AMS). This means that field devices can be reconfigured via the AMS – without applying the necessary safety measures. Hackers could potentially access the computer that runs the configuration software and alter safety parameters. So how do you protect yourself against this?

Using the HIMax controller in conjunction with the new HART solution, you can prevent configuration and defined parameters from being changed both externally and internally. All field devices can be monitored centrally, alerting staff to any issues or fluctuations in conditions. Or you could restrict data access so that only authorized personnel can use it. Issuing read and write permissions to designated staff or disabling the write function completely is another crucial area for ensuring safety at your plant. An additional key factor for security is that configuration can be managed centrally, eliminating the need for insecure handheld devices.

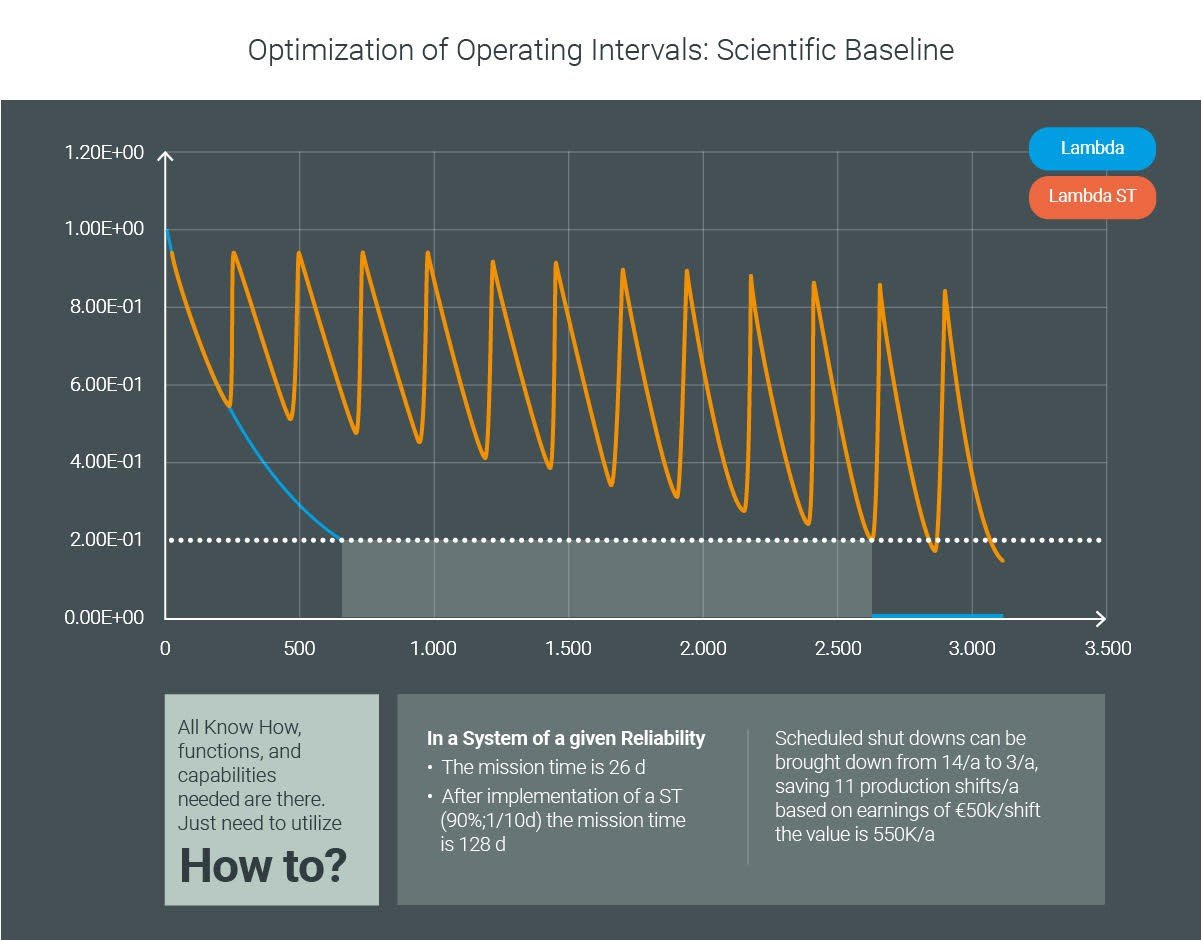

3. Extend Maintenance Intervals by Optimising Proof Tests

Proof tests play a key role in safety for field devices. However, they are often time-consuming, usually requiring multiple technicians in the field and someone in the control room to check that the safety system responds correctly. Reducing resources allocated to proof tests while remaining safe is a common concern for plant operators. Companies are now looking for ways to simplify proof tests and extend intervals, thus minimising service disruption.

How the HIMA HART solution enables you to extend service intervals

Implement Safety Data Intelligence and Leverage the Potential of Digitisation

Overall, safety data intelligence is key for ensuring safety across your entire operation. In turn, you can act on field device data that enables you to optimally run your plant, reduce the burden on your teams, and add value to your business. You maintain an accurate, up-to-date overview of the status of your plant – all of which is based on the established HART protocol. Since your existing field devices probably already support HART, implementing SIL 3 security measures to your entire plant is easy, cost-effective, and possible during operation.

Read more Mining Safety News

Add Comment