Safety in an underground construction environment requires more than simply a sound safety culture – it requires substantive subsurface construction risk expertise coupled to a willingness and capacity to prioritise recourses and respond to safety issues, writes Arnold Dix.

Australia’s extensive experience with mining well places the subsurface construction sector to successfully manage the special risks of subsurface construction. International organisations such as the International Tunnelling Association (a United Nations affiliated body) and the International Tunnelling Insurance Group (an association of the world’s tunnel insurance experts) have considered the unique risks of subsurface construction and modern approaches to managing them.

The good news is that Australia has an enviable record for subsurface construction but unfortunately deaths and injuries still occur. This article briefly explores some of the factors which contribute to the special risks in an underground infrastructure project and some of the risk mitigation strategies being used around the world.

The Code of Practice

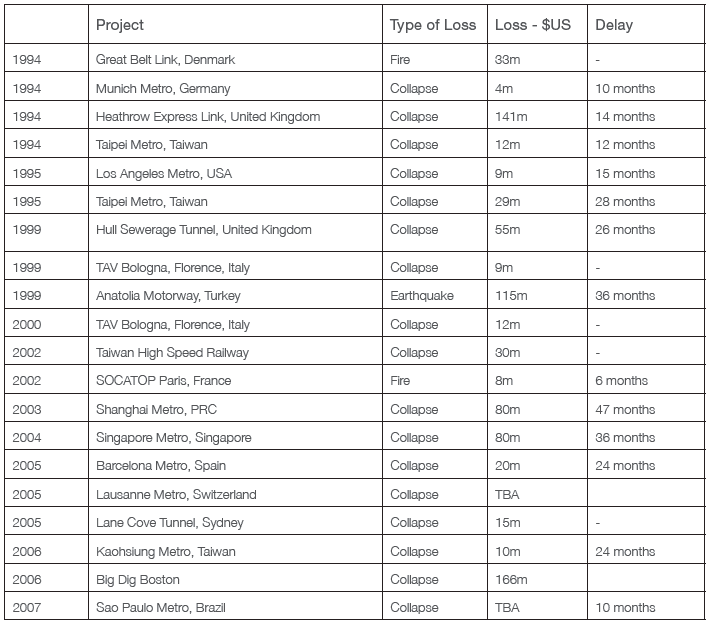

In 2006 the International Tunnelling Insurance industry published its ‘Code of Practice for Risk Management of Tunnel Works’. Publication of this Code was a reaction by the insurance industry to a spate of major tunnel collapses during construction causing loss of life and unprecedented damages. A review of catastrophic construction failures by the insurers had revealed a series of common factors in tunnel disasters. The most commonly identified factor in the catastrophic tunnel failures was failure of the underground construction project to both properly quantify and successfully mitigate known risks. The tragedy is that in most instances the collapse or other disaster was easily foreseeable but the project either chose to ignore it or failed to set up a process that could respond to identified issues.

Examples of tunnel disasters include:

A response by the insurers to formulate the Code of Practice for management of construction risk has few precedents. More remarkable is that the insurers foreshadowed that without substantial compliance with the Code insurance might be not available to a project or if a project became non compliant insurance cover would be withdrawn.

In retrospect this was clear signal to the construction industry that the insurers were firmly of the view that systematic management of risk is by far the best way of managing subsurface construction risks. There had been a practice of utilising construction insurance as the risk mitigation strategy – a practice which was insensitive to the inevitable loss of life and injuries associated with subsurface construction failures.

In order to understand how subsurface construction risks are to be addressed by compliance with the Code it is necessary to visit the Code in more detail.

The objective of the Code clearly provides that for subsurface infrastructure it is appropriate to set out the practice;

‘… for the identification of risks, their allocation between the parties to a contract and contract insurers and the management and control of risk through the use of Risk Assessments and Risk Registers.’

At Clause 2.1 of the Code the benefits of the approach mandated are described as minimising the risk of physical loss or damage and associated delays.

At Clause 3.1 of the Code the insurers invoke the legal concepts enjoyed in common law countries such as Australia and the United Kingdom by requiring the management of risk so as to ensure the residual level of risk is ‘as low as reasonably practicable’ (ALARP).

The ‘hazards’ which are to be managed by the Code specifically include (Clause 4.1.3a ‘Health and Safety’).

As is the custom within Australia on major infrastructure projects the Code requires risk assessment to be conducted which formally consider the hazards identified, their consequences and the probability of them occurring (Clause 4.2.1).

The contractor’s perspective

The ITIG Code takes a strong position with respect to the role of the construction contractors. The Code mandates demonstration of corporate competence including references from previous clients and even goes so far as to require competent staff be appointed and that those staff be identified by name.

With respect to the subject areas that expertise is mandated (and individuals named) this extends from planning and procurement to interpretation of ground conditions, designed capability, design checking, risk assessments and risk registers.

Not content to identify the experts by name the Code also requires confirmation of the experts’ availability.

In order to ensure that compliance with the Code is more than an administrative function the Code specifies that there must be personnel who are suitably qualified, experienced and competent in risk management practices.

Site and ground Investigations

By far the most significant factor for safety in subsurface construction is failing to take into account adequately the ground conditions. The Code clearly establishes a rigorous regime for ground condition assessment. It is the inputs into the systematic risk management assessments that most significantly impacts subsurface construction safety. Without meaning to discount other types of safety incidents, history tells us that catastrophic collapse of subsurface structures is a significant threat to the health and wellbeing of personnel during construction.

Construction issues

Under the Code there are positive obligations on a designer to ensure that subsurface excavation and support sequences are appropriate. The designers must ensure that it can be constructed safely given the identified geotechnical variability and construction tolerances. Importantly under Clause 8.5.5 of the Code the insurer requires the designer to provide:

‘… a sufficient number of suitably experienced and qualified persons to ensure the works are constructed appropriately.’

Under Clause 9.4.4 of the Code the contractor is required to demonstrate how its construction workers have the necessary competency to carry out the processes required for the construction of the subsurface works. In fact these requirements are even further extended to include detailed information about how construction workers training will be implemented.

The insurers seek more than administrative compliance with these requirements. The insurers’ representatives attend the construction site and make informed inquiries about how the risks on the project are being managed. This extends to actual inspections of the construction site, inspecting the risk management documents and actually confirming that what is articulated in the project documentation.

In addition to the insurers monitoring the construction, the company is required to have a monitoring plan. The insurers’ representative inspects that plan as well as the results obtained from the monitoring, in order to ensure that the construction risks are being managed appropriately.

Although the insurers are quick to admit that it is difficult to quantify the effect of this Code on Safety within subsurface construction projects, the consensus (at least amongst insurers) is that projects abiding by the Code display consistently strong safety cultures and that the Code has at the very least refocused corporate and individual attention on safety culture by linking the availability of insurance to systematic risk management.

Special risks underground

The three most common special risks for subsurface construction from a safety perspective are tunnel collapse, tunnel fire and flooding. For these purposes flooding caused by collapse is still simply considered a collapse, as the flooding of concern is from adjoining rivers, heavy rainfall and seas. The risk of collapse remains the biggest hazard in subsurface construction when the subject of more events and claiming more lives than either fires or flooding.

It is beyond the scope of this paper to explore all combinations of collapse scenarios however the combination of pressing construction timelines, an underestimation of the geotechnical complexity of the task and a failure to heed recognised warning signs of an imminent collapse are most common.

Example of how collapses can occur –

Singapore collapse

On 20 April 2004 works for the MRT Circle line failed leading to the collapse of the Nicoll Highway in Singapore. Four people died, and hundreds of millions of dollars in damage are reported to have occurred.

The project was considered by many (prior to the accident) as “low risk” because of the combination of statutory and contractual systems controls – coupled with the highly experienced teams of engineers familiar with the local ground conditions.

However the construction method to be used involved temporary works in deep soft marine clays – which were from the outset recognised as problematic. The technique adopted (but which failed) aimed to significantly reduce underground construction costs. These reduced costs of temporary underground works were the key differentiating factor between bidders in the tendering process. The cheapest bidder won.

The report, “Report on the incident at the MR T Circle Line worksite that led to the collapse of the Nicoll Highway on 20 April 2004 – by the Committee of Inquiry 10/5/05 [Chairman – Richard Magnus, Senior District Judge, Subordinate Court; Er. Dr. Tee Cee Ming, Associate Professor, Nanyang Technological University; Er. Lau Jooming, Director, Building Technology Department Housing and Development Board]”3 makes findings on likely causation at a civil law standard and recommended criminal proceedings be initiated against both corporations and individuals. The analysis in this paper solely relies upon these published findings – and neither comments on nor should be construed as commenting on the findings of the subsequent criminal proceedings.

Experience

Under the Code individual expertise and experience is very important. In the Singapore project the construction company, building contractor and local experts (whom comprised the Joint Venture) had previously (and successfully) designed and constructed deep cut and cover excavations in soft marine clay. The construction company and building contractor had also previously been united in Joint Ventures which had successfully constructed deep cut and cover excavations for the North-South/East-West MRT lines in soft marine clay. From a corporate perspective these parties were well qualified to undertake the works which subsequently collapsed.

What ‘actually’ occurred?

The Committee of Inquiry appointed by the government of Singapore to investigate the collapse found that the following chronology of critical events occurred.3

| Date | Incident | Response & Seriousness |

| 5.8.03 | Vertical Cracks over150 m long; settlement. Anticipated deflection movement 190 mm – actual movement 500 mm | 1. Work halted2. Engineering reviewed 3. Deflection rate slowed (but continued) 4. Eight meetings |

| 21.8.03 | 1 “We are taking a serious look at the temporary works … It seems that the design has been stretched to the limit. … Many instruments have breached design-allowable values. The situation is beginning to look precarious.” (email from the Design Manager of the Government Agency to the Project Director 21.8.2003) | |

| 1.9.03 | The Project Manager of the Government Agency wrote to the Joint Venture on 1.9.04 requesting they employ a replacement for the Joint Venture’s professional engineer responsible for the temporary works – because he “does not possess the requisite qualifications in undertaking full time site supervision of the complex and very deep excavation works … he is also the project coordinator and deputy project manager … it is difficult to expect that he will be able to fulfil the very onerous professional duties … to supervise the very difficult temporary works”.(This engineer was both the professional engineer for the temporary works and the project coordinator. The Government Agency initially objected to his appointment as the professional engineer as he would be too busy. On appeal the Joint Venture’s Temporary Works Engineer provided a written (personal) undertaking that he would accept and comply with his professional duties as a professional engineer for the temporary works and that he would continuously supervise the works.) | |

| 22.9.03 | A member of the independent expert panels ( the special engineering advisory panel) advised that the techniquebeing used to design the temporary works were underestimating the forces on the diaphragm walls. | |

| 9.10.03 | The Joint Venture was not prepared to reassess the design. The Joint Venture’s Temporary Works Engineeradvised that the Government Agency could not dictate how the design was to be carried out and that the Joint Venture would only reanalyse the works if the Government Agency paid. | |

| 9.10.03 | Another independent expert endorsed the first independent experts concerns stating: “the walls … are potentially severely under designed throughout … [the] contractors’ [Joint Venture’s] current temporary works design has no justifiable technical basis. In my opinion it would be irresponsible to continue with any excavation that has been designed on what we now know is an incorrect, and very unsafe, basis.” | |

| 17.10.03 | Heated exchanges between the second independent expert (retained by the Government Agency) and the Joint Venture’s Temporary Works Engineer occur (minor recheck to be undertaken). | |

| 21.10.03 | Request sent from the Government Agency to the Joint Venture to carry out a design check. | |

| 27.10.03 | The Joint Venture persuades the Government Agency that excavation should continue with close monitoring and contingency measures. | |

| 7.11.03 | The Design Manager from the Government Agency attempts to purchase a copy of software to conduct analysis. There is one copy in the Government Agency’s engineering divisions but the waiting period to use it is too long. His request to purchase a new copy is refused – in part due to lack of budget. (In January 2004 he is loaned a copy but cannot complete the analysis due to lack of engineering support.) | |

| 13.11.03 | Excessive wall deflections | |

| 31.12.03 | Excessive wall deflections | |

| Dec 03 To Jan 04 | Inclinometer reaches trigger levels until January 2004 when southern surge in wall deflection occurs | This observation was inconsistent with the Joint Venture’s explanation for the earlier failures. |

| Jan 04 | The Design Manager from the Government Agency is lent a copy of engineering program but cannot complete analysis due to lack of fulltime engineering resources – he has to return the software at the end of January 2003 without completing his analysis. | |

| 20.1.04 | The second independent expert expresses concern about excavations which were “fundamentally unsound”; he noted “there could be the potential for a major failure”. | |

| 21.1.04 | The Government Agency writes to the Joint Venture noting that analysis has not adequately predicted currentwall movement. “This is of paramount importance as the excavation is carried out adjacent to a major thoroughfare, several buildings and critical utilities …” | |

| Jan ‘04 | Independent analysis by a third independent expert retained by the Government Agency is undertaken. Heconducts geotechnical analysis which demonstrates wall failure in each of the three instances modelled. | |

| 9.2.04 | Various modelling results from the Joint Venture and the Government Agency are compared with actualobservation and persuade Government Agency not to intervene. | |

| 23.2.04 | Excessive wall deflection | |

| 4.3.04 | Excessive wall deflection | |

| 25.3.04 | Observed deflectionsexceeding revised predictions | |

| 30.3.04 | Revised deflectioncriteria exceeded | |

| 1.4.04 | Resignation of one of theGovernment Agency’s important Design Engineers | The Government Agency’s Design Engineer had been finding it difficult to cope. He resigned. The GovernmentAgency had difficulty finding a replacement for him. |

| 13.4.04 | The first independent expert meets with representatives from the Joint Venture, the Government Agency, andother independent experts, noting: • more movements and bending as being underestimated by the Joint Venture • the people using the model should come to his advanced course so that they understand its limitations • if the excavation goes beyond 25 metres, failure may occur | |

| 14.4.04 | The Senior Design Engineer for the Government Agency advises the Joint Venture’s Temporary Works Engineerto request further independent computations be made. | |

| 15.4.04 | The Government Agency’s building control unit writes a letter requesting immediate design review due to “no capacity left, even at this stage”. In the strength of the diaphragm wall (not received prior to collapse). | |

| 18 – 19April 04 | No readings taken of wall deflection | The instrument was covered with a lot of soil and so the contractor refused to read the instrument. |

| 19.4.04 | The Joint Venture submits a further review of analysis. Committee of Inquiry finds that this review was on thebasis to “… just prepare the back analysis by running the [original] model with the usual Joint Venture method.” | |

| Dec 03 to April 2004 | • 100 shops withcracks • Ground settlement • Cracks in ground | Numerous complaints. |

| 20.4.04 | • Collapse occurs• Four people killed • Large damage through project collapse | • Official Enquiry commissioned• Damages estimated at US $100s’ millions • Legal Proceedings: • Criminal and civil action against the Joint Venture partners and individual engineers likely |

As a direct result of that sequence of events the Committee of Inquiry recommended that legal proceedings be issued against corporations and individuals.3

Criminal consequences

From a corporate liability perspective the Committee of Inquiry found in relation to the circumstances preceding the collapse of the diaphragm wall that:

“A prudent and reasonably practicable thing to have been done in these circumstances would be to carry out a complete fundamental review of the design. This was, however, not done. Despite the dangerous trends and dire warning signs, [the Joint Venture] continued with the works.”

“The evidence also revealed a number of glaring inadequacies in the instrumentation and monitoring regime in the run up to the collapse.”

“Despite the [Joint Ventures] assurances that it would adopt close monitoring of the works, the readings [in a critical area] were only taken spasmodically.”

“The lack of proper monitoring meant that crucial warning signs were missed and critical reaction time lost.”

“…the deflections of the diaphragm wall…had exceeded the second revised design level during the period between 18 to 19 April when readings were not taken. This is despite the fact that readings had been stated to be taken daily in this period.” (Emphasis from enquiry report)

Criminal proceedings were taken by the Singapore Police.

Construction and safety

Had compliance with the Code been required from an early stage of the project it is likely that the probability of these events occurring would have been substantially reduced because the insurance company would have become involved in discussions regarding diaphragm wall stability as much as eight months prior to the collapse. Safety on the project would have been higher.

An insurer’s involvement is likely to have altered the balance of “power” between Joint Ventures and the Government Agency – adding weight to calls for re-assessments of the design techniques being used and more rapidly elevating the concerns expressed about the spate of underestimated deflections and cracking.

Discussion

In every project there are – and will always be – great pressures to deliver a project as quickly and cost effectively as possible. In the Singapore case despite detailed independent expert evidence about the deficiencies of the techniques to design the underground temporary structures – the works continued.

The Singapore collapse highlights the need for a dispute escalation procedure which disrespects the individual interests of a fixed price bidder in subsurface construction contracts.

The Singapore collapse also highlights the floors in having a stringent regulatory environment if the regulators do not have access to sufficient resources to initiate their own independent checks. (The Committee of Inquiry found that neither sufficient human or computing resources to re-evaluate the defective modelling were on hand despite attempts to access them).

Ultimately there is no substitute for sound, considered engineering by competent engineers working in an environment which encourages a professional approach to safely delivering underground infrastructure – ultimately safety in underground infrastructure demands expert competence.

Conclusion

The International Code of practice is likely to reduce the probability of the collapse of underground works. Because underground construction is inherently more complex than all other areas of civil engineering activities a more rigorous approach to systematically effectively managing construction risks is to be encouraged.

The Singapore collapse demonstrates that independently of the commercial, legal and financial frameworks for project delivery there must be a way to rapidly elevate technical issues for independent and effective technical evaluation. The involvement of project insurers (and their specialist experts) is a step towards achieving that objective.

The International Code of Practice for Risk Management of Tunnel Works4 provides a useful framework for working towards more sophisticated complex underground safety issue management.

Safety in underground infrastructure construction requires specialist expertise to systematically manage the unusual risks. Ultimately, safety in an underground construction environment requires more than simply a sound safety culture – it requires substantive subsurface construction risk expertise coupled to a willingness and capacity to prioritise recourses and respond to safety issues.

REFERENCES:

1. The Joint Code of Practice for Risk Management of Tunnel Works in the UK (September 2003) [International Tunnelling Association and theBritish Tunnelling Association]

2. A Code of Practice for Risk Management of Tunnel Works 12 August 2005 [International Tunnelling Association Group]

3. Report on the incident at the MRT Circle Line worksite that led to the collapse of the Nicoll Highway on 20 April 2004 – by the Committee of Inquiry 10/5/05 [Chairman – Richard Magnus, Senior District Judge, Subordinate Court; Er. Dr. Tee Cee Ming, Associate Professor, Nanyang Technological University; Er. Lau Jooming, Director, Building Technology Department Housing and Development Board]

4. Code of Practice for Risk Management of Tunnel Works; published by International Tunnelling Insurance Group, January 2006

PROFESSOR ARNOLD DIX

Professor Arnold Dix is an accomplished lawyer and scientist (Geology) who is recognised internationally for his expertise in subsurface infrastructure. The Australian Tunnelling Society awarded him the bi-annual Sir Alan Neyland medal in 2011 for his contribution to international tunnel safety. He is the Chairman of the Contractual Practices Group of the International Tunnelling Association (UN affiliate); Committee Member of PIARC (Australian Governments representative); sits on both the subsurface rail and subsurface road standards bodies in the USA (NFPA 130 & 502), consultant to lawyers DLA Piper London (subsurface infrastructure); a former Professor of Engineering and currently a Professor of Medicine – Mental Health, Science and Diversity – Tunnels UWS; he sits on and gives advice about Dispute Avoidance Boards, is a practicing Barrister; he is the Victorian Coroner’s investigator into the Burly Tunnel Fires deaths; and advises governments and Sovereign Funds on investment strategies in Asia and Europe. His focus is upon providing practical advice for safe and effective subsurface infrastructure.

Add Comment