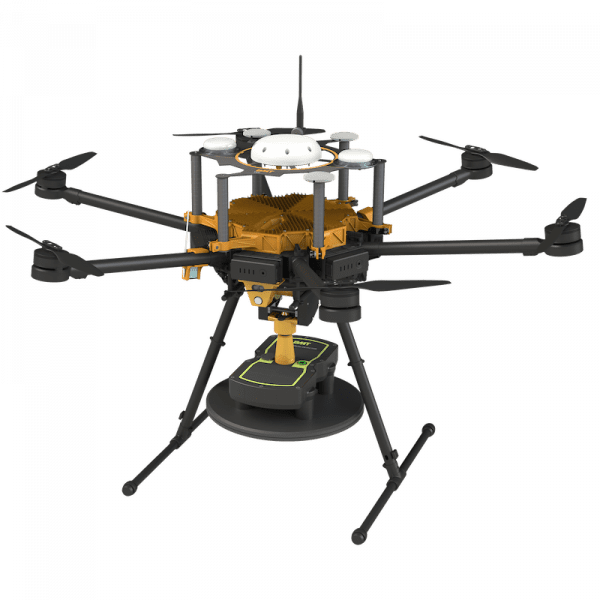

A leader in post-blast ore location and recovery, Blast Movement Technologies (BMT), part of Hexagon, released FED 2.0. This specially fitted UAV offers a safer, more expedient solution to post-blast monitoring with improved detection depths of up to 12 metres. By adhering to strict ‘stand-off’ guidelines, FED 2.0 enables the swift retrieval of BMM (Blast Movement Monitor) location data post-blast, without the need to walk the muck-pile.

Hexagon new split colour feature improves fragmentation analysis

Hexagon and RealWear mitigate safety hazards

BMT released its first UAV detector in November 2019, establishing an alternate, semi-automated solution to retrieve BMM sensor data. Like its predecessor, FED 2.0 is based on the DJI Matrice M600Pro flying platform, but now features an automated Winch mechanism to lower the detector closer to the surface and away from the main UAV body. This not only ensures greater detection depths but also lessens the interference from the motor and blades.

The Winch was developed in partnership with Australia-based, unmanned systems specialist, Insitu Pacific, a subsidiary of The Boeing Company. Insitu ensured that the new winch technology works seamlessly with the existing FED ground control software, as well as introducing several other user experience improvements.

FED 2.0 features an automated flight control and customizable flight plan. It has a built-in GNSS receiver to enhance positioning information and a vertical and horizontal collision detection system. It can also resume the mission after low battery replacement from the point where it was suspended. The on-board computer allows for immediate processing of incoming data, ensuring access to the movement data while resolving safety and environmental considerations.

“With many mines focussed on recovering more ore quickly and safely, our FED 2.0 continues our journey towards an autonomous future,” said BMT CEO, Jacques Janse. “This safety aspect, along with the increased detection depths, opens up the ability to use our BMM system in more mines.”

Read more Mining Safety News

Add Comment